Careers

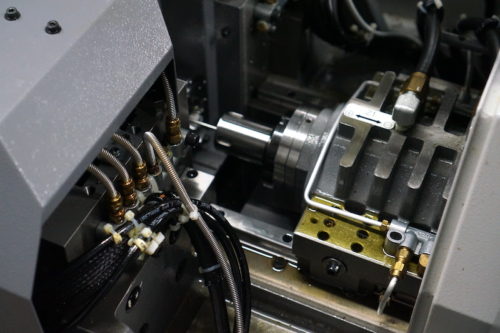

Dongguan CNC Machining supports sophisticated applications and repeatedly meets complex challenges in the aerospace, industrial, defense, and medical industries.

Join our team and learn the timeless, exacting standards of “Swiss Machining” — accuracy, quality, and performance.

Click on the Apply Today button to access an application, or browse our current job listings below. Email application and resume to Careers@dongguancncmachining.com

Current Openings

Machine Shop Assistant

We are looking for motivated individuals to join our team as a Machine Shop Assistant where you will earn as you learn!

No previous machine shop experience is required for the Machine Shop Assistant position and it is a great stepping-stone to a career as a machinist!

10 indications that a Computerized Numerical Control (CNC) machining career at Dongguan CNC Machining could be right for you.

- The idea of doing highly skilled work on complex machines captures your interest.

- You want to work with your hands.

- You like to use your critical thinking skills to solve complex problems.

- You are detail oriented.

- You like closure and enjoy seeing a project through from beginning to end.

- You would describe yourself as a process person.

- You love learning something new all the time.

- You have a lot of mental and physical stamina and you want to use it.

- You view challenges as opportunities to grow and expect to be able to learn and advance in your career.

- You want to be respected and rewarded for your accomplishments and skills.

If this sounds like you, apply today!

Position Summary

Assists with incoming material and shipping/receiving tasks. Assists machine operators to increase the flow of production in various departments.

Essential Duties and Responsibilities

- Assist with incoming materials, as needed (receive material, clean material for storage, prepare material for machining, etc.)

- Assist with draining and prepping chip barrels and scrap

- Assist with parts washing (operation of solvent tank and heat tank, manual rinsing, etc.)

- Assist with shipping (scale count product, box product for finished goods/shipment, weigh product for UPS pick-ups, etc.)

- Assist operators with loading bars, clearing chips, adding oil, checking parts, etc

- Operate burr bench to deburr parts as needed

- Maintain clean work areas (light janitorial duties, such as sweeping, breaking down boxes, and light machine maintenance, such as cleaning oil around machines, removing chips, etc.)

- Perform all other duties as assigned

Qualifications:

- High school diploma or GED

- Two years of full or part-time work experience

- Ability to read, write, and speak English

- Mechanical, numerical, and verbal abilities

- The ability to adapt to the world of work as demonstrated by a history of:

- strong job performance

- following an organization’s processes and procedures

- active learning

- good interpersonal skills

- helpfulness/teamwork

- being able to handle the physical demands of jobs

Entry-Level CNC Machinist

Position Summary

Operates computer numerical control (CNC) machines to fabricate parts. Loads materials and tooling into machine, cycles machine, detects malfunctions in machine operations and/or tooling, and inspects product for conformance to specifications.

Essential Duties and Responsibilities

To perform this job successfully, an individual must be able to execute each of the following essential duties satisfactorily:

- Maintain machine production after setup has been made by others

- Remove, sharpen, reset tools, and make slight adjustments when necessary

- Read and interpret specifications for the part (drawings, setup sheets, inspection sheets, work orders etc.)

- Retrieve tooling for current and/or upcoming jobs

- Detect any defective raw materials and report to department lead

- Cycle machine to produce parts and troubleshoot any errors or minor mechanical issues during the production run

- Perform routine inspections of machined products according to specifications and document results

- Note any changes that should be made to documents containing product specifications and communicate with department lead (if applicable)

- Tear down machine according to instructions (remove tooling, return tooling to designated locations, etc.)

- Report any major mechanical issues or necessary equipment maintenance to department lead (if applicable) and/or management

- Perform all other duties as assigned

Qualifications:

- High school diploma or GED

- Technical degree in machine tooling or equivalent work experience

- Ability to read, write, and speak English

- Mechanical, numerical, and verbal abilities

- The ability to adapt to the world of work as demonstrated by a history of:

- strong job performance

- following an organization’s processes and procedures

- active learning

- good interpersonal skills

- helpfulness/teamwork

- being able to handle the physical demands of jobs

Email This Page

Email This Page