High-quality Precision CNC Machining Services

Dongguan CNC Machining is an ISO 9001:2015-certified company specializing in precision machined components. Our services extend from standard CNC turning and milling to also include Swiss machining for jobs requiring the utmost precision. Thanks to our expertise in this area, we’ve come to be known as a reputable provider for industrial, aerospace, defense, and medical machining, among others.

Precision Machining Services at Dongguan CNC Machining

At Dongguan CNC Machining, we continually invest in equipment and machinery that grants us advanced precision manufacturing capabilities. We specialize in Swiss-style machining, as well as more traditional precision CNC processes.

Swiss Turning and Machining

Swiss Turning and Machining

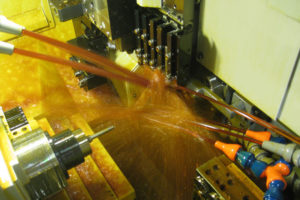

Our cutting-edge facility is stocked with multiple Swiss-style turning centers with advanced capabilities. Using these machines, we can achieve ultra-precise dimensional tolerances within ±0.0001 inches and cycle times as low as 10 seconds. These machines boast nine axes of machining motion, making it possible to perform multiple tasks in a single cycle.

Swiss machining also saves time by enabling lights-out machining, which means the work centers can operate unattended for extended periods of time. This is possible thanks to a combination of automated feeding and handling, all monitored by reliable control software. As a result, Swiss machining drastically increases production volume while minimizing labor costs. Our Swiss machining production services are available for components with diameters up to 1.25 inches and are compatible with virtually all common metals and plastics.

CNC Turning

CNC Turning

We also use traditional CNC turning methods, especially when we need to accommodate larger component sizes than our Swiss machines can handle. Our CNC turning centers are suitable for components up to 18 inches in length with diameters up to 1.625 inches. McCormick has been providing high-quality turned components for over 20 years, constantly drawing on the latest innovations in machining technology. By employing only cutting-edge machinery and knowledgeable operators, we’ve consistently provided tolerances as tight as ± 0.0001″ on length and diameter and ±0.00008″ on roundness.

CNC Milling

CNC Milling

Our final area of expertise is CNC milling, which is known for producing parts with extremely tight tolerances. Milling uses rotating cutting tools to shape the workpiece, whereas turning rotates the workpiece itself. We employ a variety of vertical milling centers (VMCs) with high-speed spindles reaching 12,000 RPM to ensure rapid and accurate production of milled components. Our expert operators take care to set up the machinery with the best tool for each given task, resulting in tolerances as tight as ±0.0003 inches for surface features while still maintaining rapid turnarounds.

Our milling capabilities include a full range of metals and plastics in both high- and low-volume runs. We also offer a variety of finishing options, such as micro-deburring, to ensure that your components are finished to your exact specifications.

CNC Machining Services From Dongguan CNC Machining

CNC machining applies precision processes well-suited to fabricating industrial, aerospace, defense, and medical components. At Dongguan CNC Machining, we are experts in this type of high-tech manufacturing and are uniquely prepared to handle the small, intricate components that our clients require.

To learn more about our advanced capabilities and competitive pricing, contact Dongguan CNC Machining today.

Email This Page

Email This Page