CNC Swiss Turning Services

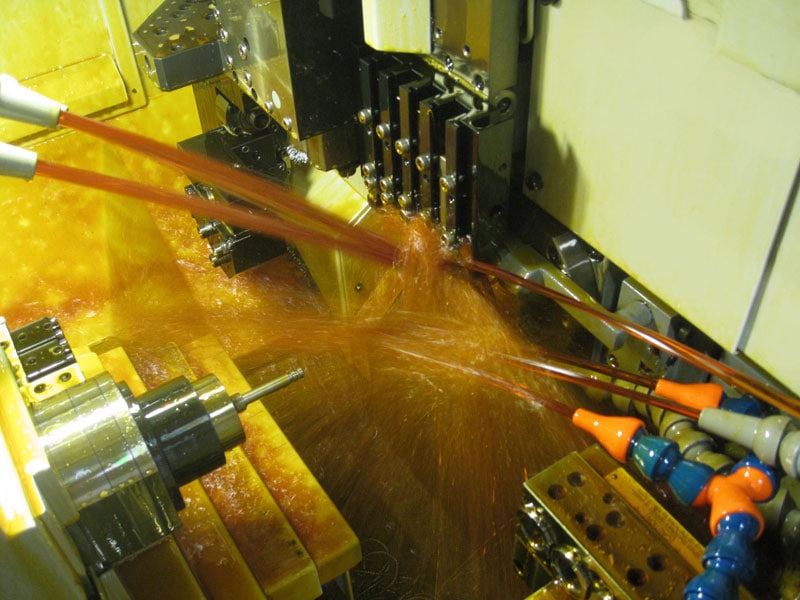

As part of our comprehensive service offering at Dongguan CNC Machining, we provide Swiss CNC turning services for the high-speed, high-accuracy production of parts with diameters up to 1.25″. Inside our modern facility, we have several Swiss-style turning centers with a range of capabilities. This allows us to efficiently meet the unique requirements of a wide range of applications.

Our Swiss CNC turning capabilities provide a number of important advantages. In addition to extreme accuracy (we can hold ultra-precise dimensional tolerances to ±.0001″) our lathes feature up to 9 axes of machining motion. Live tooling and multi-axis capabilities allow us to perform multiple machining tasks from a single set-up, while simultaneous axis control adds an extra measure of precision to operations such as pinch milling, turning, and ID/OD threading. All of these Swiss-style turning capabilities result in cycle times that can be as low as 10 seconds.

Another major benefit of precision Swiss CNC machining is the ability to run lights-out. Automated bar feeding and part handling, combined with sophisticated control systems, allow our machines to run unattended for extended periods. This enables us to produce high volumes of parts and part families with minimal labor costs.

All types of metal can be Swiss machined, including aluminum, high-strength steels, exotic alloys, and more. We also handle parts made from a range of plastics. As an ISO Compliant facility, we take a holistic approach to quality to ensure the integrity of everything we produce. Our customers are our most important asset, so we are committed to providing an exceptional level of quality and service to promote long-term business relationships.

To learn more about our Swiss machining capabilities or to obtain a quote, contact us today.

Swiss CNC Turning Capabilities

- Machining Processes

-

Lights-Out Machining

Multi-process Machining

- Processes

-

Broaching

Hard Turning

OD/ID Threading

TappingThread Milling

Thread Rolling

Thread Whirling

- CNC Swiss Turning Centers

-

Cincom L32 XII

- Max Machining Dia.: 32mm (1.25″)

- Max Spindle Speed: 8,000 RPM

- 9 axes of motion

- B-axis allows drilling of angled holes/features

Cincom D25 VIII

- Max Machining Dia.: 25mm (1.00″)

- Max Spindle Speed: 10,000 RPM

- 12 axes of motion

- Opposing gang posts allow simultaneous rough and finish

- B-axis allows drilling of angled holes/machined features

Cincom L20 X

- Max Machining Dia.: 20mm (.79″)

- Max Spindle Speed: 10,000 RPM

- 8 axes of motion

Cincom L20 VIII

- Max Machining Dia.: 20mm (.787″)

- Max Spindle Speed: 10,000 RPM

- 7 axes of motion

Cincom R07 VI

- Max Machining Dia.: 7mm (.275″)

- Max Spindle Speed: 16,000 RPM

- 8 axes of motion

- Opposing gang posts allow simultaneous rough and finish

Cincom A32 VII

- Max Machining Dia.: 32mm (1.25″)

- Max Spindle Speed: 8,000 RPM

- 7 axes of motion

Cincom L20 XII

- Max Machining Dia.: 20mm (.787″)

- Max Spindle Speed: 10,000 RPM

- B-axis allows drilling of angled holes/machined features

- 9 axes of motion

Cincom L20 IX

- Max Machining Dia.: 20mm (.787″)

- Max Spindle Speed: 10,000 RPM

- 7 axes of motion

Cincom K16 VII

- Max Machining Dia.: 16mm (.625″)

- Max Spindle Speed: 15,000 RPM

- 7 axes of motion

- Additional Equipment Capabilities

-

- Up to 8 axis Machinery Axis

- Up to 9 axis

- 4 axis contouring

- 2000 psi high pressure coolant

- Live tooling up to 7500 RPM

- Simultaneous axis control facilitating pinch milling, turning, and ID/OD threading

- Up to 39 tools for high complexity work pieces

- Tolerances

-

Ultra Precision: ±.0001″

Diameter: ±.0001″Length: ±.0001″

Roundness: ±.00008″

- Swiss CNC Materials (Metals)

-

Aluminum

Brass

Bronze

Carbon Steel

Copper

PlasticsStainless Steel

Steel

Tool Steel

Titanium

Exotic Alloys

- Secondary Services Offered

-

Light Mechanical Assembly

Micro-deburring

Vibratory finishing

- Production Volume

-

Prototype

Low Volume

High Volume

- Lead Times Available

-

Quoted on job by job basis

Emergency services available

Additional Information on Our Swiss Machine Shop

Industries Served by Swiss CNC Machining

Swiss turning is an ideal option when components must meet exacting tolerances for straightness or concentricity. Such requirements are common in industries such as medicine or military operations, where any deviations in a component’s size could put human lives at risk. These needs are also found in industries that work with small or delicate electrical components.

Dongguan CNC Machining has a great deal of experience serving a broad range of industries. Here are some of the sectors we most commonly work with:

Industrial Swiss CNC Machining

Industrial components are a special kind of CNC challenge, requiring tight tolerances on small components. Before Swiss turning, the set-up for such orders was labor-intensive and error-prone. However, with the precise multi-axis motions of a Swiss-style turning machine, we are able to navigate these challenging projects with ease.

Our production case study serves as an excellent example of our capabilities in this area. We served as the primary contractor for the product, which was a 0.472 inch long, 0.118 inch in diameter dowel pin custom-manufactured for a product used in the electromechanical industry.

We determined that Swiss turning would be the best tool for primary processing, and we chose a machine with high-pressure cooling capabilities to remove chips and maintain a sharp edge on the cutting tools. Leveraging this technology, we were able to exceed typical processing speeds while still producing a reliable, high-quality product.

Welding Components

Welding components often have similarly rigorous design constraints. One of our longstanding customers in the welding sector trusted us with the manufacture of a gas lens for use in TIG welding. Lenses of this type must conform to very specific measurements because they regulate gas flow for the welding machine. This particular design also called for complicated design features, including cross holes and stamped markings.

To create this component, we programmed a Swiss machining center to drill, mill, and stamp the workpiece, using the machine’s high-pressure cooling system to enable more efficient processing. We also took advantage of the Swiss-style center’s multi-tool, multi-axis capabilities to combine multiple machining steps into each pass.

Medical Swiss CNC Machining

Surgical instruments must be manufactured to perfection. Even the most minor aberration in the surface finish of a medical device can harbor bacteria, potentially resulting in serious infections. This was the challenge for one of our medical projects, a surgical mallet staff with complicated design features like flanges, fillets, and grooves.

We used a high-performance grade of stainless steel for the project, which we machined using Swiss-style turning centers to achieve the precise tolerances demanded by our medical clients. Using these CNC techniques, we managed tolerances of ±0.002 inches for the diameter. Once formed, we performed all sanding and polishing necessary to achieve a completely smooth surface free of dangerous nicks or abrasions.

Aerospace and Defense Swiss CNC Machining

Our customers in the aerospace and defense industries are known for demanding absolute precision and consistency. In this instance, a supplier we’d worked with before returned to us to craft a complicated military trunnion. The design called for close tolerances with complex geometric and surface features. We determined that Swiss turning would allow us to fulfill these requirements while keeping the turnaround time and budget requirements under control.

Using our Cincom K 16E center, which offers a large and flexible tool capacity, we achieved ±0.0001 inch tolerances, verified by on-machine vision inspection followed by caliper and micrometer measurements. We were able to maximize speed, accuracy, and repeatability using Swiss machining to keep costs down.

Advantages of Swiss Machining

CNC machining on its own is a powerful tool, but Swiss machining improves performance on many of the key metrics that our clients care about. The benefits of Swiss machining include:

- Cost savings. A typical Swiss-style center can complete both milling and turning in a single setup, incorporating multiple tools and axes of motion. This minimizes labor costs as the machines require little intervention once set.

- Precision. Swiss machining offers maximum precision with dimensional tolerances as low as ±0.0001 inches. This is a key benefit for industries that demand accuracy and repeatability above all else.

- Speed. A Swiss center performs multiple operations in a single setup, which drastically reduces cycle times and increases production volume. Also, since Swiss centers can operate lights-out, we are able to produce components near-continuously, further reducing lead time.

Swiss CNC Machining Services From Dongguan CNC Machining

Swiss machining combines turning and milling processes into a single precision process well-suited to fabricating industrial, aerospace, defense, and medical components. At Dongguan CNC Machining, we are experts in this type of high-tech manufacturing and are uniquely prepared to handle the small, intricate components that our clients require.

To learn more about our advanced capabilities and competitive pricing, contact Dongguan CNC Machining today.

Email This Page

Email This Page