CNC Turning Services

Since its founding in 1996, Dongguan CNC Machining has grown to be a major supplier of high-quality turned parts used in aerospace, medical, defense, and general industrial applications. By leveraging the latest in precision machining technology, we achieve fast cycle times while consistently holding tolerances as close as ± .0001″ on length and diameter and ±.00008″ on roundness. Our CNC turning capabilities are supported by a knowledgeable and responsive staff of manufacturing and customer service professionals who are committed to delivering an exceptional level of service.

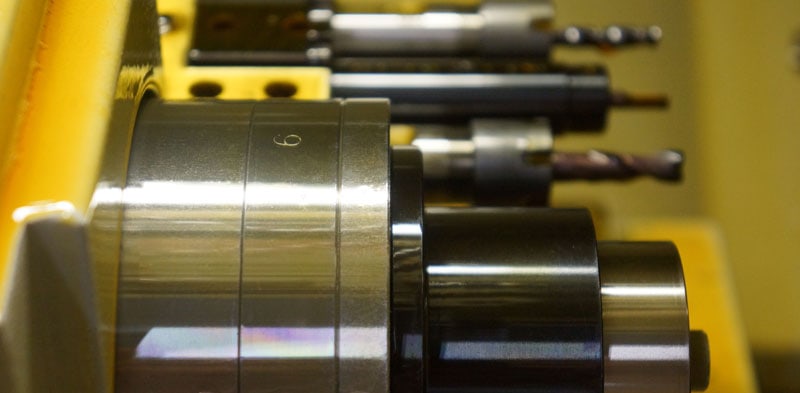

Our CNC turning equipment incorporates high-speed spindles and sub-spindles, which allows us to machine using up to three tools simultaneously. Combined with live tooling capability, we can machine features such as complicated thread patterns and intricate internal features with minimal setup. Advanced technology CNC control systems in combination with intelligent tooling allows for highly accurate and repeatable production at higher rates. The consistency and efficiency of our CNC turning process produces parts that exhibit the highest level of quality and craftsmanship.

We are experienced at turning parts constructed from all different types of metals, including high-performance grades and exotics. Our technicians are also proficient with the unique requirements of machining various types of plastic. We turn parts with maximum dimensions of 18.00″ in length x 1.625″ in diameter, and manage quantities that range from short run to high volume production.

Our ISO Compliant Quality Management System ensures we maintain quality and accuracy. We continually monitor tolerances to ensure we meet critical dimensional requirements. Agile and responsive, we are positioned to take on your most challenging projects.

To learn more about our CNC turning capabilities or to obtain a quote, contact us today.

CNC Turning Capabilities

- Processes

-

OD/ID Threading

Tapping

Thread MillingInternal Forming

Broaching

- CNC Turning Center

-

Miyano GTY

- Max Machining Dia.: 41mm (1.625″)

- Sub Spindle Speed: 6,000 RPM

- Max Spindle Speed: 5,000 RPM

- CNC Lathe 10 HP

-

Okuma

- Max Machining Dia.: 41mm (1.625″)

- Max Spindle Speed: 4,200 RPM

- Additional Equipment Capabilities

-

- Max machining length: 18″

- Simultaneous machining with 3 tools

- Live tooling up to 6000 RPM

- Tolerances

-

Diameter: ±.0001″

Length: ±.0001″

Roundness: ±.00008″

- Materials (Metals)

-

Aluminum

Brass

Bronze

Carbon Steel

Copper

PlasticsStainless Steel

Steel

Tool Steel

Titanium

Exotic Alloys

- Secondary Services Offered

-

Light Mechanical Assembly

Micro-deburring

Vibratory finishing

- Production Volume

-

Prototype

Low Volume

High Volume

- Lead Times Available

-

Quoted on job by job basis

Emergency services available

Additional Information

- Industry Focus

-

Aerospace

MedicalDefense

Industrial

- Industry Standards

-

ISO 9001:2015 Compliant

RoHS Compliant

Conflict Free Minerals

- File Formats

-

PDF

Auto CAD

DWG DrawingsDXF

Parasolids

Solid Works

Email This Page

Email This Page