Archives

Archive: Oct 2022

What Is the Difference Between CNC Turning and Milling?

Leave a CommentComputer numerical control (CNC) machining is a manufacturing process that uses computerized controllers to operate machine tools. This technology has been around for decades and has been used extensively in the aerospace, medical, industrial, and electrochemical industries.

CNC milling and turning are two of the most common processes in CNC machining. Though both involve the use of computer-controlled machinery, there are several key differences between the two.

Here, we will take a closer look at those differences to help you better understand which process is right for your project.

What is CNC turning?

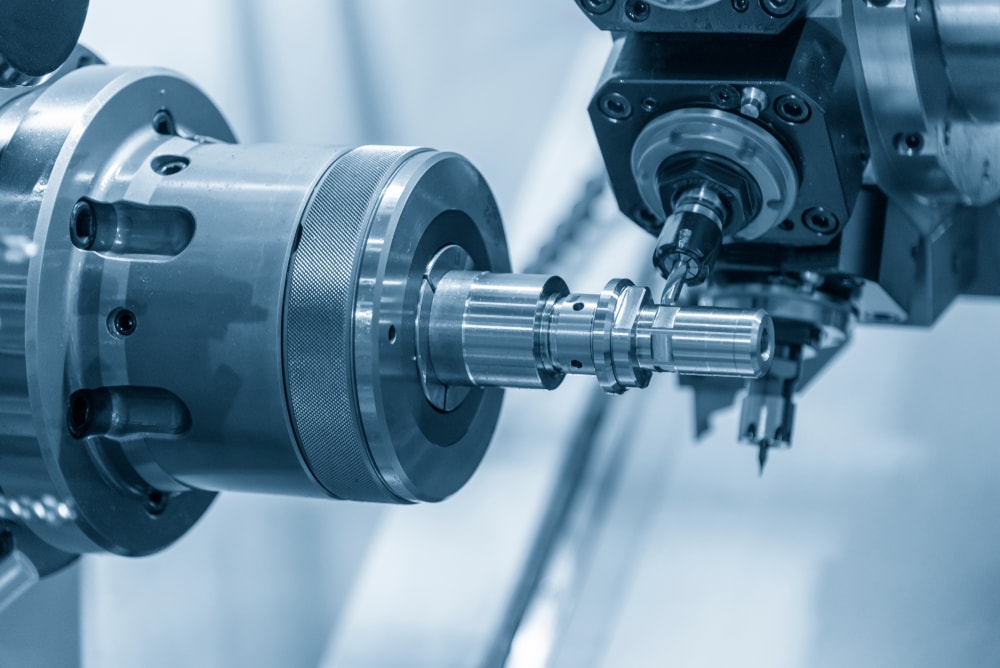

CNC turning is a machining process that uses computer numerical control (CNC) to rotate a workpiece while it is held in a chuck. This rotating motion, combined with the movements of the cutting tool, allows for precise and repeatable machining of cylindrical parts.

CNC turning can be used to create parts of various shapes and sizes, from small components to large-scale workpieces. The process is well suited for high-volume production and one-off parts, making it a versatile manufacturing solution.

CNC turning is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape. The process can be performed on various materials, including metals, plastics, and composites.

Let’s dive into the benefits of using CNC lathes for turned parts.

The benefits of CNC turning

The benefits of CNC turning are numerous and can be extremely helpful in a variety of manufacturing settings. The most obvious benefits are the following:

- CNC turning can significantly increase the speed and accuracy of production.

- CNC turning can produce parts with very tight tolerances.

- CNC turning can create complex shapes that would be difficult or impossible to create using other methods.

- CNC turning is a very fast and efficient way to produce parts in large quantities.

- CNC turning can be used to produce parts from a variety of materials, including metals, plastics, and composites.

- CNC turning is a very versatile manufacturing process that can be used to create a wide variety of parts and products.

Another significant benefit of CNC turning is that it can help to reduce the amount of waste produced during manufacturing. This is because CNC machines can be programmed to produce parts with very specific dimensions, which reduces the need for material trimming or other forms of waste.

Overall, the benefits of CNC turning can be beneficial for a variety of manufacturing businesses. CNC machines can help to improve the speed and accuracy of production while also reducing waste. These benefits can ultimately lead to increased efficiency and profitability for a business.

Now, let’s talk about CNC milling.

What is CNC milling?

CNC milling is a machining process that uses computer-controlled rotary cutting tools to remove material from a workpiece. Tool paths are created from a CAD file and uploaded to the CNC machine, which then controls the motion of the tool to remove material and create the desired shape. The process can be performed on various materials, including metals, plastics, and composites.

CNC milling is a versatile machining process that can be used to produce a variety of parts with a high degree of accuracy. CNC milling can also be used to produce parts with a variety of surface finishes. It is commonly used in the aerospace, automotive, medical, and energy industries.

So why should you use CNC milling?

The benefits of CNC milling

CNC milling offers a number of benefits over traditional machining methods. The following are some of the most notable benefits of CNC milling:

- CNC milling allows for precise and repeatable machining of parts.

- CNC milling can be used to create complex shapes and geometries.

- CNC milling can be used to create parts with a high degree of dimensional accuracy.

- CNC milling can be used to create parts with a smooth surface finish.

- CNC milling can be used to create parts with various material properties.

- CNC milling can be used to create parts with different thicknesses and sizes.

Overall, CNC milling is a popular manufacturing process due to its many benefits, including increased accuracy and repeatability, increased productivity, increased versatility, and reduced waste. This technology can be used to create a wide variety of parts and products, from simple prototypes to complex end-use components.

Final thoughts: Difference between CNC turning and milling

CNC milling and turning are both processes that are used to create parts and products from raw materials. Both processes can be used to create a variety of different shapes and sizes, and both require the use of a CNC machine.

However, there are some key differences between CNC milling and turning. CNC milling involves rotating cutting tools to remove material from a stationary workpiece, which is typically square or rectangular. CNC turning utilizes a lathe to rotate primarily round bar stock while using cutting tools to remove material.

Ultimately, the decision of which process to use depends on your project’s specific requirements. CNC milling and turning can produce high-quality parts and products.

What Is a Ferrule?

Leave a CommentA ferrule is a small metal or plastic ring used to reinforce a joint between two pieces of material. Commonly used on electrical cables and fiber optic cables, ferrules create a stronger connection than would be possible with the materials alone. This makes them ideal for applications where high levels of stress or vibration are present.

Ferrules are an important part of any cable assembly. They help to ensure reliability and performance in even the most demanding environments. When selecting ferrules for your application, it is important to consider the material, size, and attachment method that will best meet your needs.

What are ferrules made of?

A ferrule is typically made of brass, bronze, copper, stainless steel, or other metal. It may also be made of plastic, rubber, or other non-metallic material. The material must be strong enough to withstand the pressure or force exerted on it.

What does a ferrule look like?

A ferrule is a small cylindrical fitting that is used to join two pieces of tubing or piping together. Fittings like this are common in many industries, including manufacturing, plumbing, and automotive. A ferrule typically has a male-threaded end that screws into a female-threaded coupling or adapter. This type of connection is known as a threaded connection. The other end of the ferrule is usually flared out or beveled, which helps to create a tight seal when the two pieces of tubing are joined together.

What is a ferrule used for?

As stated above, a ferrule is a metal or plastic sleeve that is placed over the end of a pipe to reinforce it and prevent it from becoming damaged. The ferrule also helps to create a seal between the pipe and the fitting, which prevents leaks. Fittings that have been fitted with a ferrule are typically more durable and reliable than those without.

The use of a ferrule is not limited to pipes; it can also be used on cables and other types of tubing. When applied to cables, the ferrule helps to prevent the wires from fraying or breaking. This type of reinforcement is especially important in high-stress areas, such as where the cable is bent or twisted.

Applying a ferrule is typically a simple process. The ferrule is slid over the end of the pipe or cable and then tightened in place. This can be done by hand, or with the use of a tool. Ferrules are available in a variety of sizes to accommodate different types of pipes and cables.

Once in place, the ferrule creates a physical barrier that prevents the cable from being pulled out of the connector. This provides added security for critical applications such as data centers and telecommunications networks.

Ferrules are an important part of many plumbing and electrical systems. They help to ensure that the system is strong and durable and that it will function properly for many years.

Pipes that are not properly reinforced can be susceptible to damage, which can lead to leaks or breaks. This can cause significant problems, such as water damage to a home or office. In some cases, it may even be necessary to replace the entire pipe.

Cables that are not properly reinforced can also be susceptible to damage. This can lead to signal loss or interference, and in some cases, the cable may need to be replaced.

Ferrules help to prevent these problems by reinforcing the pipe or cable and creating a seal. This makes the system more durable and reliable, and less likely to experience problems.

Overall, plastic or metal ferrules are a simple and effective way to reinforce your system. They can help to prevent leaks, breaks, and signal loss, and make your system more durable and reliable.

Should you use ferrules?

Ferrules are used to provide a neat, finished look as well as to prevent the wire from fraying. In some cases, ferrules may also be used to provide electrical insulation.

So, should you use ferrules? It really depends on the application. For example, if you’re working with high-voltage wiring, then ferrules are a must in order to prevent electrical shocks. In low-voltage applications, ferrules may not be necessary.

We’re the Custom Ferrules Experts

Custom ferrules are an essential part of many industries, and Dongguan CNC Machining is a leading manufacturer of custom ferrules. We have the experience and expertise to create plastic or metal ferrules that meet the specific needs of our clients.

We use the latest technology and equipment to create high-quality ferrules that are designed to last. Our ferrules are available in a variety of materials, including stainless steel, aluminum, and brass.

We can also create custom ferrules that are designed to meet the specific needs of our clients. Contact us today to learn more about our custom ferrules and how we can help you meet your needs.

Email This Post

Email This Post